Instructions, Care Info, and Tutorials

Select the tool you would like instructions for using the buttons below.

- Fire-Heated Branding Iron

- Electric Branding Iron

- Branding Food/Baked Goods

- Additional Tips

- Changing Branding Heads

- Drill Press Mounting Irons

- Propane Iron

- Fire-Heated Livestock Irons

- Electric Livestock Irons

- Freeze Livestock Branders

- BBQ Steak Branding Irons

- Caring for Your Branding Heads

- Handheld Steel Stamps

- Steel Plate Stamps

- The TagMate Tag Marking System

- Brass Stamps

- Magnesium Plate Stamps

- Steel Type

- Hand Stamp Holders

- Impact Presses

BRANDING IRONS UNLIMITED PRODUCTS

INFINITY STAMPS PRODUCTS

-

Basic Operating Procedure

- Before placing the branding head over open flame, make sure handle rod is tightly screwed into your branding head.

- Be sure to use thick gloves.

- Preferably, use a small propane torch such as a Benzomatic to heat the engraved face of the branding die.

- Practice on scrap pieces of your material(s) first for optimized proficiency.

- The length of time for holding the head over open flame can vary depending on a few factors such as how close you hold the head over the flames, the head size, the material you intend to brand, and how dark you wish the mark to be. Dwell time on the item being branded may vary from one application to the next, as the head will gradually lose heat. If branding multiple items, it may be necessary to reheat the head and results may vary, depending on the degree to which the branding head is reheated.

NOTE: Weather conditions and draft may also change the time and frequency for heating and reheating the branding head.

Additional Tips and Useful Branding Information

WARNING: Never heat the iron beyond a dull gray hue and NEVER leave the branding iron in fire unattended.

Note: It is not recommended to put the branding iron directly into a campfire as this may overheat the branding head and cause damage to the brand.Make Sure Iron is Firmly Attached to Handle

Practice Makes Perfect

It is imperative that you practice on scrap pieces of the material(s) you intend to mark before branding your actual items. This will provide you the opportunity to find just the right degree of heat for your specific application(s) and will help you become proficient.

-

The Basics of Branding

- While heating up your branding iron, when it is idle, and while cooling it off to room temperature, the branding iron must remain in a horizontal position, resting on the provided stand or cradle.

- Time needed for heating up the branding head: Allow 20-40 minutes. Factors that can affect heat-up time include: Branding head size, temperature control unit setting, and changes in work area conditions such as draft, temperature and humidity.

- Optimal dwell time (Holding branding head in contact with surface being branded): 3-15 seconds – Factors that can affect dwell time include: Branding head size, temperature control unit setting, and weather conditions around work area.

- Start off any branding session by pre-heating your branding head for 20-40 minutes, while your temperature control unit is set to maximum. Make sure to test-brand some scrap pieces of your material(s) so that you can adjust the temperature control unit based on your test-branding results.

NOTE: Never leave your branding iron in an upright position. Always rest the iron horizontally on the stand or in a cradle. Heat rises and damages heating tool components and can melt or burn the handle.

Changing the position of your electric branding iron from horizontal to vertical before it cools off to room temperature may result in internal damage and void warranty.

IMPORTANT: For branding in countries with voltages other than 120V, 60 Hz (U.S. voltage) outside North America, make sure to use our 220V-240V branding equipment.

Branding Procedure

- Choose a safe, well-ventilated work area for all your test-branding and branding sessions.

- Make sure your scrap pieces are on your work surface, and ready for test-branding.

- Ensure that the items you intend to brand are smooth, flat and dust free. Then set them on a flat, smooth and clean heat resistant work surface.

- Plug your temperature control unit (TCU). into an electric outlet and plug your branding iron into your TCU.

- Make sure your branding head is firmly attached to your heating tool and is resting on the provided stand or cradle, or on a heat resistant safe surface that cannot burn, nor catch fire, such as a brick.

- For Plastic: A good starting point is to set your TCU between 20% and 30% (depending on the kind of plastic). Wait about 15 to 20 minutes for your branding head to heat up. Then your branding iron should be ready for you to start test-branding. Place the heated branding head in full contact with the surface of your scrap piece for about 1 second, remove and check the mark you have obtained. If necessary, adjust your TCU percentage setting, as well as the dwell time.

- For Leather: A good starting point is to set your TCU between 40% to 60%. (Lower percentage suitable for lightweight leather and higher percentage for heavier-weight). Wait about 15 to 20 minutes for your branding head to heat up. Your branding iron should then be ready for you to start your test-branding. Place the heated branding head in full contact with the surface of your scrap piece for about 3-5 seconds, remove and check the branded mark obtained. If necessary, adjust your TCU percentage setting as well as dwell-time.

- For Wood: A good starting point is to set your TCU to 70%. (Lower percentage suitable for softer woods and higher percentage for hard woods). Wait about 20 minutes for your branding head to heat up. Your branding iron should then be ready for you to start your test-branding. Place the heated branding head in full contact with the surface of your scrap piece for about 5-10 seconds, remove and check the branded mark obtained. If necessary, adjust your TCU percentage setting (higher or lower) as well as dwell-time.

- After obtaining a few test-marks, pause a few seconds to allow your branding head to recover and regain heat.

- Once you obtain the desired branded test-marks on your scrap pieces, proceed to brand your products.

Tip A: Before starting a new branding session, we recommend test-branding prior to branding the actual products.

Tip B: The next time you are ready to brand additional items, if temperature conditions have changed, or if your work area is drafty, you may find it necessary to slightly adjust your TCU accordingly.

Tip C: It takes longer for the iron and head to cool off than to heat up.

-

When using an electric heating tool, you will need medium temperatures for branding bakery goods such as burger buns, bread and tortillas. Set your temperature control unit to the middle setting that allows you to create a branded image in a reasonable amount of time. Using the highest setting will most likely speed things up, but may overburn the item creating a less legible image, as well as shorten the life of your branding tool.

Use an iron holder to isolate your branding tool from coming in contact with any metal surfaces while heating it up and during your branding session too. Direct contact of your branding tool with metal will increase heat-up time and potentially branding time as well. Using the iron holder will also prevent the iron cord from direct contact with the hot tool.

If the heated Stainless Steel Branding head tends to stick to your baked goods, do NOT immerse or dip it in oil. Instead you may spray a light coat of oil on a baking sheet or on a sheet of aluminum foil, and then lightly touch the branding head to the oiled surface during your branding session, as needed.

When you complete a branding session, never use anything except time to cool off your hot branding iron. Quenching in any liquid may damage your branding tool and will void warranty.

-

Prolong the Life of Your Branding Iron

Be sure your branding head is firmly secured to your branding tool. This will ensure good heat transfer for best branding results. This will also protect the tool from over-heating. Using a temperature control unit for branding any material will further prolong the life of your branding iron.

Practice Makes Perfect

It is imperative that you practice on scrap pieces of the material(s) you intend to mark before branding your actual items. This will provide you the opportunity to find just the right degree of heat for your specific application(s) and will help you become proficient.

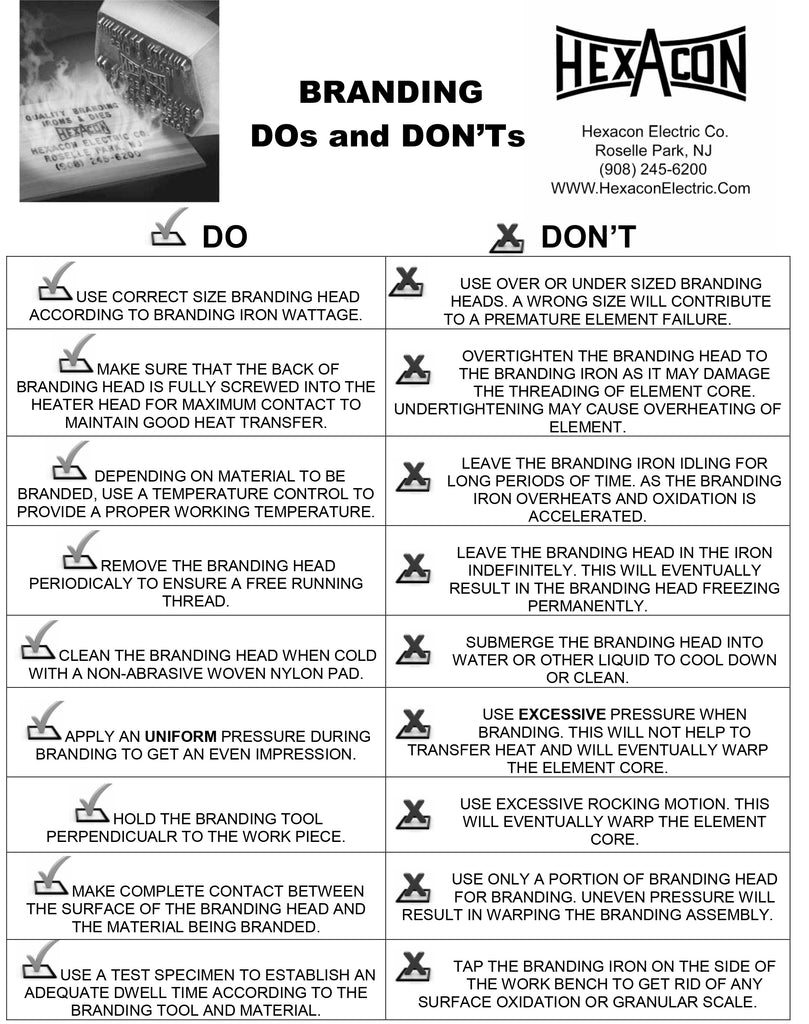

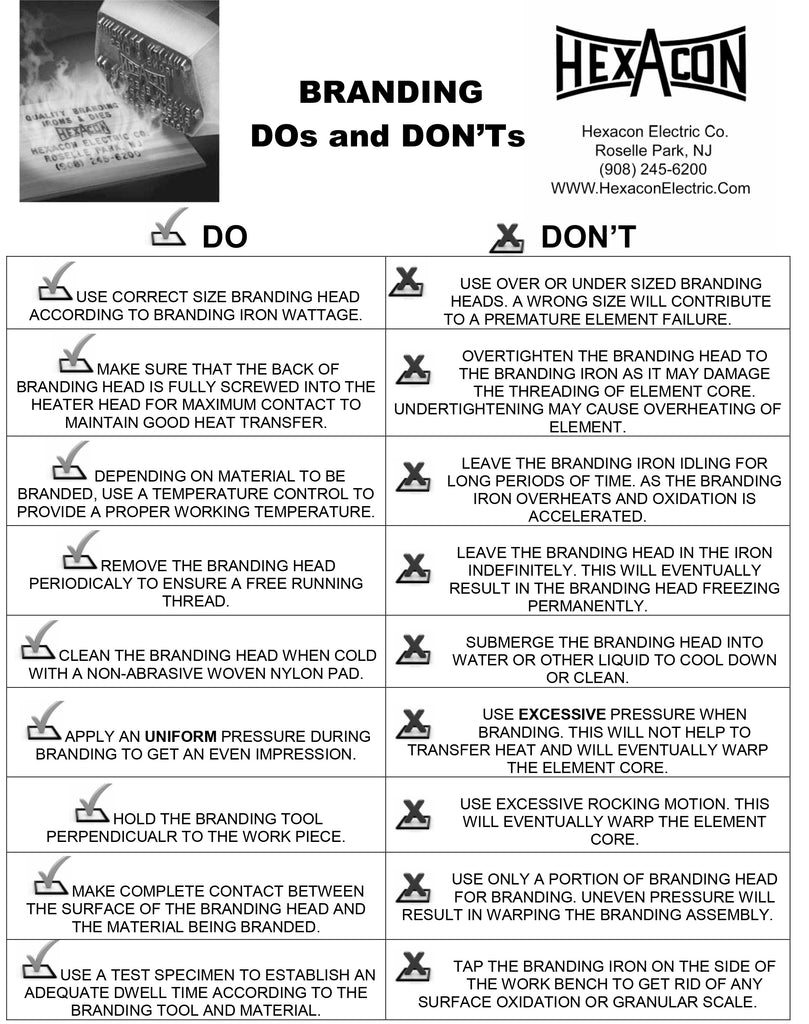

The DOs and DON’Ts of Branding

Be sure to read Hexacon’s DOs and DON’Ts (below) for good pointers on how to properly use and maintain your new electric branding iron.

-

The following procedure is intended only for those who have multiple branding heads designed to work with our large style Hexacon electric heating tools. If you have only one branding head, we recommend that it remains connected to the heating tool, and checked for tight connection periodically. If you have a small style branding head that is paired with either a 80, 175, or 200 watt handheld electric tool the branding head will simply unscrew from the threaded adapter that is in the electric heating tool.

Items needed for detaching and reattaching branding heads:

- Vice

- Channel lock or adjustable wrench

- 2 Cloth rags

- If the branding head and heating tool are hot, allow them to cool off. Then wrap the head in a rag to protect it from nicks and scratches.

- Place the wrapped head between the vice jaws and tighten until it is secure. Do NOT over tighten. Make sure the heating tool is upright and that the entire barrel is above the vice jaws and accessible.

- Wrap the second rag around the barrel. Adjust your channel lock or adjustable wrench to fit around the barrel and tighten.

- Turn counter-clockwise until the heating tool is loose enough to turn by hand.

- To reattach or attach another head to the heating tool, screw it in by hand clockwise as tight as possible.

- Wrap the head and place it between the vice jaws with the heating tool upright, as explained in step 2 above.

- Wrap the second rag around the hexagonal barrel and adjust channel lock as explained in step 3 above.

- Turn clockwise until secure, without using excessive force.*

*It is important that the head is securely attached to the heating tool. This ensures good heat transfer and prolongs the life of the heating tool.

-

When using a Drill Press Mounting branding iron, you will need to either remove the safety switch of your drill press or unplug it.

- Insert the shank of the Drill Press iron into the chuck of your drill press and secure in place by tightening the chuck.

- You will need to use your drill press feed lever only for lowering onto, and raising off the items being branded.

- Be sure the damper arm on the drill press arm is working properly. The arm should not snap back or cause any vibrations.

- While the iron is off check the level of the branding head to the surface of your material. If it is not level proceed with leveling the branding head using the video embedded below as a guide.

- If you choose to create a jig on your drill press table, make sure your drill press table is level. This will ensure that every item will be marked exactly in the same spot. It will also increase efficiency.

CAUTION: Do not exert additional force beyond the Drill Press tool springs’ maximum compression. Additional force may result in damage to your branding equipment.

-

Using the Branding Iron for the First Time

Out of the box, the Pro-1000 Propane Branding Iron needs adjustments before it can be used. The branding head is pressed up against the burner for shipping purposes. When not in use, the branding head can be in this position for compact storage.

Watch the video below or read on for instructions on using your propane branding iron for the first time.

To adjust the branding head to proper branding position, take the following steps:

- Over a flat, level surface, proceed to remove all packaging materials from the branding head.

- Rest the branding iron on your chosen flat surface, to ensure the branding head will not fall to the floor and possibly get damaged while you’re making the necessary adjustments.

- Using the included hex key, loosen the two black hexagonal screws that hold the branding head in place. Do NOT unscrew them completely.

- Slide the branding head away from the burner so that the back of the branding head is about 2 inches away from the burner opening.

- Tighten the two black hexagonal screws till the branding head is firmly in place. Do NOT over-tighten.

- Your Pro-1000 Propane Branding Iron is now ready to use. First review and then follow branding instructions below.

Preparation Instructions

- When you are ready to use your PRO-1000 Propane Branding tool, carefully read these Instructions & Care information pages from beginning to end. We recommend that you do this before each branding session.

- Select a well- ventilated space that is a safe distance from any source of ignition, flame or flammable materials.

- Make sure you are mindful of your surroundings. Remove any objects that may melt or catch fire, as this tool’s burner flame widens when it hits the back side of the attached branding head, which also heats up to high temperatures. (Flame temperature can be about 700° F)

- Keep children and pets away from your selected work area.

- Take every precaution to ensure safe use of this branding tool by following all the instructions included throughout these Instructions & Care pages.

What you will need:

Hex key (included)

20 lb. liquid propane gas cylinder/tank

26mm wrench or adjustable wrench

Flint striker, long lighter, long match or another safe ignition device

Brick or similar burn-proof flat object on which you can rest the hot branding head

Connecting the PRO-1000 Propane Iron to a Propane Source

The PRO-1000 includes a Sievert Pressure Regulator 3091. Use of a pressure regulator reduces the cylinder pressure, allowing a safe and consistent gas flow from a standard 20 lb. steel LPG (liquid propane gas) cylinder/tank, commonly used for BBQ purposes.

- Place the regulator in contact with the propane cylinder valve. The regulator connector has a left-handed thread, requiring counter-clockwise tightening.

- Slip the connector nut onto the propane cylinder valve thread and then turn counter-clockwise.

- Use a 26mm wrench, an adjustable wrench or another suitable tool, to tighten the nut to a firm connection.

Lighting the Propane Branding Iron

Before you attempt to light your branding tool burner, be sure you have chosen a safe and well-ventilated work area (see Preparation above). Check for leaks (see Leakage Checklist below) and be sure to follow safety precaution at all times (see Safety Information below).

- Set a brick (or similar object) on your chosen melt & burn-proof flat work surface, to rest the branding head while heating it up, during a branding session, and while the branding head cools down.

- Check to see that the adjustment knob on the burner is completely closed, by turning the knob clockwise till it stops turning.

- Open the propane cylinder valve until it stops turning.

- Hold the Propane Branding Iron away from your body and in a safe direction. Then, slowly turn the adjustment knob counter-clockwise, an approximately quarter-turn. Listen to hear the propane gas flowing out the burner.

- Due to air trapped in the propane hose, it may take a few seconds before only propane starts flowing through and out the burner.

- Using a safe ignition source (flint striker, long match or lighter) carefully light the propane flowing out the burner.

Heating the Branding Head

At this point, set the lit branding tool down, with branding head resting on the brick (or similar burn-proof flat object) for approximately 10 minutes, to allow the branding head to heat up to a branding temperature.

NOTE: Heating time may vary, depending on branding head size, space between head and burner, flame intensity, and weather conditions.

Prevent Accidents — Do NOT leave branding tool unattended.

Branding Instructions

- Before branding your products, test-brand sample pieces of the same material, to see if your branding head is at an optimal branding temperature for your application. For lighter or darker/deeper marks, adjust the burner flame intensity and/or the dwell time. TIP: After each adjustment, allow a few minutes for branding head temperature to stabilize.

- Dwell time is an important factor to consider. The longer the dwell time, the darker and deeper the mark will be. After finding a good dwell time, it can still vary from one branding session to the next, depending on burner flame intensity, material type and its humidity contents, as well as change in weather conditions. Typically for wood, dwell time would be about 2-8 seconds. If necessary, adjust dwell time and/or flame intensity.

- Based on the outcome of step 1 and 2, proceed to brand the products that need to be marked.

Extinguishing the Burner Flame

When you are done branding your products, follow the procedures below to extinguish the flame.

- Turn the burner adjustment knob clockwise until it stops and the flame is gone.

- Close the propane cylinder valve until it stops turning. NOTE: The flame may be extinguished and the tank is shut, yet the hose is still filled with propane.

- Turn the burner adjustment knob counter-clockwise about a half-turn. You should hear the propane gas escaping from the burner.

- When you no longer hear gas escaping through the burner, turn the adjustment knob clockwise to the OFF position until it stops.

- At this point, the branding head is still very hot. Let the branding head air-cool for at least 1 hour before attempting to touch it. Make sure others do not have a chance to accidentally touch or come in contact with the hot branding head. Do NOT leave your branding tool unattended.

- To check if the iron is still hot, steadily and gradually bring your hand closer to the branding head, making sure you do NOT touch it. With your hand carefully hovering over the branding head, feel for heat waves rising from its surface. If you feel no heat rising, the branding head is most likely cool enough to touch.

TIP: Using a heat-resistant mitt or glove is recommended.

Changing or Switching the Branding Head with Another

Before attempting to detach the branding head, be sure the branding head is cool.

- Rest your branding tool on a flat and level surface (same work surface you have used for heating up the branding head is fine), to ensure that the branding head will not drop to the floor or ground (and possibly get damaged) while detaching it.

- Using the included hexagonal wrench, loosen the two black tightening screws that hold the branding head in its branding position, till the grip no longer restricts the two rods from sliding.

- Hold the branding head and pull it away from the burner, until the two rods slide out and are no longer connected to your propane branding tool.

- Put the detached branding head aside, kept attached to its two rods. Choose a secure storage place, free of sharp objects (to prevent nicks and scratches). Proceed to slide the two rods of your other BIU Propane Branding Head into your branding tool rod holes located in the rod holder (labeled “Branding Irons Unlimited”). NOTE: Our propane branding heads always include two rods that perfectly fit into the holder of your PRO-1000 propane branding tool.

- Adjust the spacing between the back end of the branding head and the burner opening to about 2 inches apart.

- Tighten the black screws to a firm grip with the provided hex key. Do not over-tighten.

- Your PRO-1000 Propane Branding tool is now ready to be used. When you are ready to brand, review & repeat the instructions on these pages, while observing all safety precautions.

Leakage Checklist

Before you attempt to light the burner of your PRO-1000 Propane Branding tool, check for any leaks from the cylinder itself (your propane source), as well as any that may be between your propane cylinder and your branding tool burner.

To check for leaks, follow the following steps:

- Close the adjustment knob of your branding tool burner.

- Open the propane cylinder valve slowly.

- Brush or spray the connections with leak spray or a soapy solution (soapy water).

- Look for leaks which will occur as bubbles.

- If bubbles occur, close the gas cylinder valve. Check all connections for tightness and/or damage.

- After making any necessary adjustments, repeat the process from step 1 until no leaks are detected and no bubbles form. If leaks persist, contact the appropriate distributor for further assistance.

Propane Branding Iron Safety Information- Always shut off the gas supply by closing your propane cylinder valve.

- Never use your cylinder valve or regulator as a handle to lift the tank. This may break the connections or damage the tank.

- Always change and set your propane cylinder upright, in a safe place outdoors, inaccessible to unauthorized individuals, away from any source of ignition such as naked flames, lit pilots or electric wires.

- Never check for leaks with a naked flame. Use soapy water or leak-detecting spray only.

- If you discover or suspect that there has been a leak, you must be extra careful and evacuate the gas by adequate ventilation. LP Gas is heavier than air and can easily accumulate in trenches, poorly ventilated spaces and below ground level.

- Never try to repair or modify a defective regulator yourself.

- Never leave your PRO-1000 branding iron unattended, with a flame-lit burner and while branding head is cooling off.

- Be mindful of your surroundings. Do not use your PRO-1000 branding tool in poorly ventilated spaces or around objects that can catch fire or melt.

- Keep the propane hose a safe distance away from the flame-lit burner and hot branding head.

- Keep a fire extinguisher handy whenever using your PRO-1000 Branding tool.

- Do not leave your branding tool unattended. Make sure others do not have a chance to accidentally touch or come in contact with the hot branding head.

-

IMPORTANT

- Do NOT let the branding iron come into contact with water, mud, dirt, sand or ashes.

- When heated, keep away from any flammables and materials.

- These branding irons are intended for branding livestock only. Do not use for any other branding purposes.

Basic Operating Procedure

- Clip any excess hair off the area where the animal will be branded.

- Use an experienced team of people for this task.

- Use a large blowtorch to heat the branding head. Make sure to move the torch across the full surface of the brand to ensure uniform heating

- Dwell time is about 10 seconds. Branding head needs to be held on the animal with moderate pressure, until the surrounding skin turns a dark copper color. Dwell time may vary, depending on weather conditions, animal breed and/or age.

Additional Tips*

- When heated properly, the iron should appear to be the color of ashes. A branding iron must burn sufficiently to remove the hair and outer layer of skin. Acids and other branding fluids are not permitted.

- Branding irons should not be used by inexperienced hands. Adequate time must be allowed when applying brands and various other conditions must also be considered. Wet or damp cattle should not be branded as the brand will scald the hide and cause a scar or blotch. Livestock will carry their brands for life – take time to apply with care.

- Do not apply a light “hair” brand. It will soon disappear leaving no permanent mark.

- Do not brand on top of any part of a previous brand.

- Depending on the temperature of the branding iron, age of the animal, hair cover, etc., the branding process should take from five to ten seconds.

- Remember, you only need to burn the hair and outer layer of skin. Too deep a brand will result in bleeding and take longer to heal.

- A proper brand should be the color of saddle leather when the brand is removed. Rocking the iron during the branding process will insure uniformity on all areas of the brand.

- Keep the branding irons free of scale, burnt hair, etc. by cleaning with a steel brush.

*Source: South Dakota State Brand Board

-

IMPORTANT

- Do NOT let the branding iron come into contact with water, mud, dirt, sand or ashes.

- When heated, keep away from any flammables and materials.

- These branding irons are intended for branding livestock only. Do not use for any other branding purposes.

Basic Operating Procedure

- Clip any excess hair off the area where the animal will be branded.

- Use an experienced team of people for this task.

- After plugging in the Branding Iron, allow 90 seconds for it to reach the proper temperature.

- Dwell time is about 10 seconds. Branding head needs to be held on the animal with moderate pressure, until the surrounding skin turns a dark copper color. Dwell time may vary, depending on weather conditions, animal breed and/or age.

Additional Tips*

- When heated properly, the iron should appear to be the color of ashes. A branding iron must burn sufficiently to remove the hair and outer layer of skin. Acids and other branding fluids are not permitted.

- Branding irons should not be used by inexperienced hands. Adequate time must be allowed when applying brands and various other conditions must also be considered. Wet or damp cattle should not be branded as the brand will scald the hide and cause a scar or blotch. Livestock will carry their brands for life – take time to apply with care.

- Do not apply a light “hair” brand. It will soon disappear leaving no permanent mark.

- Do not brand on top of any part of a previous brand.

- Depending on the temperature of the branding iron, age of the animal, hair cover, etc., the branding process should take from five to ten seconds.

- Remember, you only need to burn the hair and outer layer of skin. Too deep a brand will result in bleeding and take longer to heal.

- A proper brand should be the color of saddle leather when the brand is removed. Rocking the iron during the branding process will insure uniformity on all areas of the brand.

- Keep the branding irons free of scale, burnt hair, etc. by cleaning with a steel brush.

*Source: South Dakota State Brand Board

-

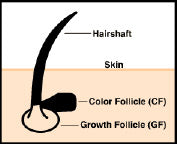

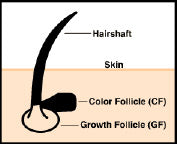

Livestock Skin Anatomy

The skin of the animal contains millions of hairs which make up the animals coat. Figure 1 is an enlarged, simplified drawing of one hair shaft with its color (pigment) producing follicle (CF) and its growth follicle (GF), both shown below the skin.

Under normal circumstances, hair grows as a clear shaft (like a clear straw) from the GF. On colored animals, pigment (black, brown, red, yellow etc.) is added from the CF below the skin to the clear hair shaft, which gives the hair its color.

When the intensely cold iron used in freeze branding is placed on the skin for the correct time and at the correct pressure, the cold temperatures destroys the CF’s at the brand site so they no longer can produce pigment; however, the hair still continues to grow for the GF’s. The result is that hair at the brand site contains no pigment and appears white. This is the desired result-a uniform, white brand. If the iron is pressed to the skin for a shorter period of time and/or with less pressure that required, some hairs grow in colored and some hairs grow in white, so the brand has a streaked appearance. If the iron is held on a longer period of time, the cold destroys the GF’s as well, so that no hair grows at all. On light colored animals the bald is desirable because the dark skin with no hair shows up better that a white brand.

Recommended Materials & Equipment

- Holding chute or some other positive device to keep the animal from moving

- Container large enough so the irons can stand upright when the heads are submerged in the coolant

- Coolant-Dry Ice and Alcohol or Liquid Nitrogen

- Electric clipper (surgical blade preferred)

- Grooming brush for cleaning the brand site

- Gloves

- Stopwatch

- Squirt bottle

- Brass Freeze Branding Iron

- 99.9% alcohol (lower percentages contain water which can cause an ice layer to form during branding and decrease the penetration of the cold through the skin)

Brand SelectionFreeze branders are cast of copper alloy (brass) which is generally preferred because of its temperature holding capacity. Standard sizes are between 2” and 6” in height. They have a variety of face sizes, not vented and an 18” steel handle for convenient application. Corresponding numbers are stamped on top of the handle, enabling you to choose the proper iron without removing the brander for the coolant container.

Selecting a Branding Site

Before branding, care should be taken in selection of the site to be branded. Each state or county may have its own regulations regarding the placement of the brand on the animal. Be sure to check with your county clerk, county extension agent or state brand inspection agency about branding and brand ownership regulations.

When branding on the shoulder, be sure the iron head is not partially on a thinner muscle mass over the scapula with the remainder if the iron head on a heavier, deeper muscle mass not covering bone. Unequal head pressure can produce a non-uniform brand. This situation can also arise when branding on the rear end; a portion of the branding iron head is partially on the rear of the pelvic bone and the remainder is on the muscle below.

Using Dry Ice & Alcohol

Alcohol will be needed for this branding method. Among refrigerants used are methyl, ethyl, or isopropyl alcohol. It is very important that any alcohol used be 99% in strength or it will turn to slush at the extremely low temperature needed (approximately 160 to 180 degrees below zero). Acetone is another very good refrigerant, because it is clear and the quantity of dry ice in the container is always visible. Some of the suppliers of acetone are drug companies, welding supply firms and animal health supplies. After extensive use, alcohol will lose strength because of its tendency to absorb moisture. Alcohol should be changed after branding approximately 150 head of livestock. Care should be taken when handling 99% alcohol it is extremely inflammable.

Using Liquid Nitrogen

Liquid nitrogen is a very good coolant and will cool to a temperature of approximately 240 to 250 degrees below zero. Liquid nitrogen is available through artificial insemination organizations and welding supply firms. Care should be taken when handling liquid nitrogen because of its extremely cold temperature.

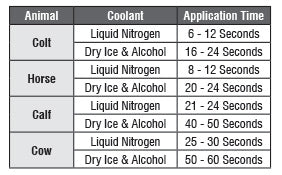

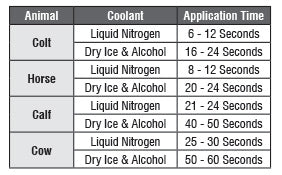

Branding Times

Dwell Times While Branding

Branding times vary according to the type of metal in the irons (times shown here are for brass freeze branding irons available from BIU) and the age (skin thickness) and color of the animal. Branders should calibrate their freeze branding irons by branding the recommended times and keeping accurate records of times and results.

Branding Procedure

- Chill the irons in the desired coolant. Pour enough coolant into the container to adequately cover the heads of the irons by 1”. The surface of the coolant will appear to boil when the irons are introduced into the coolant, when this boiling subsides the irons are as cold as the coolant will allow and are ready to use.

- Restrain the animal with your desired method, squeeze chute or calf table for cattle and twitch or stock for horses, making sure the site to be branded is accessible.

- If the animal needs to be sedated, consult your veterinarian.

- Clean the brand site of foreign material.

- Clip the brand site as square as possible, particularly at the bottom, to aid in square placement of the brand.

- Thoroughly dry the brand site if the animal is sweating or is wet from the rain or washing.

- Squirt room temperature alcohol over the brand site thoroughly covering the entire shaved area. This removes some skin oils and helps transfer cold from the iron head to the skin.

- Immediately after the alcohol soak, quickly remove the appropriate iron from the container, align it properly and firmly press the iron squarely on the brand site. As the iron is pressed to the skin, the stopwatch should be started. Hold the iron firmly applying 35 to 45 pounds of steady pressure, with a slight rocking motion. When the appropriate time has elapsed on the stopwatch, the iron should be immediately removed from contact with the skin.

- After branding, immediately place the iron back in the container of coolant. It should be re-cooled completely before it is used again.

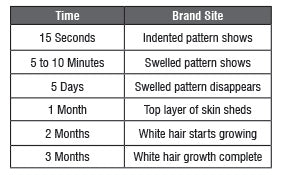

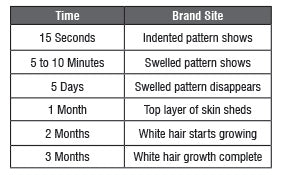

Post Branding Results

Immediately after freeze branding, you will see a frozen indentation in the animal’s skin. Within five minutes the indentation will disappear and swelling will begin. The brand will be readable but the swelling will cause the mark to have two or three times the thickness that the actual finished brand will have. The brand will be swollen for 48 to 72 hours. After the swelling dissipates the brand may not be easily seen. About 20 to 30 days the brand will begin to get flaky and scaly. By the third or fourth week the scab will start to turn loose. Once the scab is gone, white, peach fuzz type hair should appear in 30 days. Full hair growth will depend upon the time of year the brand is applied.

Important Precautions

Dry ice and the cold liquid can cause injury to humans, and precautions should be taken so these do not come in contact with your skin. Acetone and alcohol are flammable and should be used in open air or a well-ventilated building. Avoid smoking and keep this material away from open flames or electric cattle prods. Vapor from this liquid is also dangerous to the tissues of your eyes and nose.

Before ordering a freeze brand as proof of ownership or a registered brand, contact your state brand inspection agency. The use of such irons is subject to laws relative to each individual state or county.

Materials used and procedures are based on factual information, but not guaranteed.

Information gathered with the help of:

Paul Riggs, Southwest Livestock Services, Forney, TX

Doug Householder, Ph.D., Professor and Extension Horse Specialist, The Texas University System

-

Heating the BBQ Steak Branding Iron

Before you start branding actual food items, make sure the branding iron is hot enough for the desired branded mark. As different food products require different degrees of heat. You may want to brand samples prior to branding the actual steaks, etc. that will be served.

The steak branding irons we offer can be heated up on gas grills as well as charcoal and propane grills, on a gas stove, or with a propane torch.

The iron should be very hot. As soon as it starts turning a dull gray or slightly red, immediately remove it from the heat source.

Apply even pressure for a few seconds (about 2-4 seconds). If necessary, gently rock your iron to ensure the entire image comes in full contact with the surface of the food you’re branding.

Depending on the food and weather conditions, it may be necessary to re-heat your iron after each or a couple of branded marks.

WARNING: Whenever using a steak branding iron, be extra cautious and wear heat-resistant protective gloves.

Test Branding

Branding different food products requires different degrees of heat. Your first few branded marks may not be perfect. That is why we recommend test-branding samples of your food products in preparation for further branding. After a few branded marks, you should get a good sense of how long it takes to heat up your steak iron and how many seconds to keep it in contact with the food you will be branding.

Branding Tips

SAFETY NOTE: Branding irons are designed to get hot and need to be handled with care. Generally, once the branding iron is hot enough, it will be hot about 4″ – 5″ up the rod. While this is far from the top end of the branding iron, we always recommend handling the branding iron with some sort of kitchen mitt or leather grilling gloves.

- Apply the techniques you acquired while test-branding.

- Take the fully-heated branding iron and place it firmly on the spot you selected for the branded mark. Keep the branding head on the surface and do not lift during the process.

- In some cases a gentle rocking motion of the iron will ensure a complete image transfer.

- The number of seconds to keep the iron in contact with the food depends on how hot the iron is, weather conditions and the food product you will be branding.

- Remember that heat is spent during the branding process, and that you will need to reheat your iron for continued use.

-

Cleaning Your BBQ Steak Branding Iron

After your steak iron has completely cooled off, simply wash it with soap and water, dry it well with a kitchen towel and then briefly over a flame.

If residue remains, use a stainless steel bristle brush to remove it. Place the branding head under running water to rinse off any remaining loose residue. Remember to thoroughly dry your entire branding iron, first with a kitchen towel and then briefly over an open flame. Taking these simple steps will prolong the life of your steak iron.

Steak Branding Irons Made of Iron (Classic)

With proper care, this branding iron should last a long time. As this branding iron is not stainless steel, it can rust if not cleaned and dried immediately.

Gently hand washing the iron with a little dish washing soap and water will usually clean it. However, we can’t stress enough that this steak iron needs to be dried extremely well right away, first using a dry kitchen towel and soon after holding the iron over an open flame for a few seconds till completely dry. If this iron should rust, you can simply clean it with a small stainless steel wire brush and rinse off any loose debris by holding the iron under a running faucet.

Once more, remember to wipe it dry and complete drying by placing your clean iron directly in an open flame.

Steak Branding Irons Made of Stainless Steel (Original & Western)

With proper care, this branding iron can serve you for a long time. This branding iron is stainless steel but still requires proper cleaning to ensure a sanitary branding iron. Hand washing this iron with dishwashing soap and water will usually clean it well and drying it thoroughly soon after is recommended. If residue remains on your iron, you can easily remove it with a small stainless steel wire brush and rinse off any loose debris by holding the iron under a running faucet.

Custom Steak Branding Irons

Please refer to Stainless Steel Branding Irons above.

-

Cleaning Your Brass and Stainless Steel Branding Heads

Keep your Branding Heads clean by using a Brass Wire Brush for brass branding heads and a Stainless Steel Wire Brush for stainless steel branding heads to remove any and all residue.

NOTE: Brushing the front of your branding head will help obtain clear branded marks.When branding with an electric heating tool, with or without a temperature control unit:

After use, if you find your branding head takes longer to heat up, take the following steps:

- Check to see that your branding head is still firmly attached to your heating tool. If not, re-tighten it in a vice (avoid over tightening).

- Allow the branding head to slowly cool off completely (do not speed up cool-off time) and then make sure your branding head is firmly attached by turning it clockwise. (Avoid over-tightening in vice).

- If any build-up (residue) is detected on the back side of your branding head, brush it all off (Use our brass brush for brass heads or our stainless steel bush for stainless steel heads)

- Reattach cleaned branding head to your electric heating tool and tighten properly in a vice (avoid over-tightening). NOTE: Following the above listed steps will restore optimal heat transfer from your electric heating tool to your branding head, ensuring best performance. Proper use, as described, will also protect and prolong the life of your electric heating tool.

Storing Your Branding Heads

When not in use, keep your branding head(s) wrapped in a soft, lint-free cloth. This will help prevent your head(s) from getting nicked or scratched. Electric irons should be unplugged until you are ready to use them again. Remember to remove the cloth wrapped over your branding head before plugging in your iron and before turning on your temperature control unit.

-

Handheld Steel Stamps

Tools you will need: A 16 oz hammer, a pair of safety glasses, a pair of work gloves and a 1" thick steel bench block.

- Set the products you intend to stamp on your workbench

- Place your steel bench block under good lighting and secure in place (recommended).

- Put on your gloves and safety glasses.

- Hold your steel hand stamp in one hand between your thumb and index finger, making sure the stamp groove is in contact with your thumb (groove is located on front side of the stamp).

- Place the stamp face directly on the spot you wish to imprint. Pick up your hammer and, before striking your stamp verify that it’s vertical and not tilting in any direction. Check to see that the entire stamp face is in full contact with the surface of your product.

- Strike your stamp with moderate force only once, to prevent a double image and ensure a clear and complete imprint.

All Steel Stamps & Plates – Preservation and Care

- Do not attempt to use your steel stamps or steel plates for marking hardened steel. Hardened steel products cannot be stamped with steel stamps.

- When you're not using your steel stamps, to prevent rusting, we recommend that you store your stamps in a dry, airtight container. A Tupperware container or a cookie tin box should do the trick.

- Oiling your steel stamps before you store them will also protect them from rusting. Canola oil will do just as well as a product called All Purpose Lubricant.

- If you live in humid climate and find that your steel stamps have some rust on them, you can use a dry Scotch Bright scouring pad (a dish-washing pad) to remove the rust.

- A Steel Sandpaper sheet can also be used. Make sure to avoid scouring or sanding the face of your stamp so it doesn't get scratched or rough.

- When you're done removing the rust off the shaft of your stamp(s), wipe it off with a dry paper towel or clean cloth and oil them promptly thereafter.

-

Steel Plate Stamps for Use in Presses

Marking instructions would depend on the application (material being marked), and would also vary according to press used. If your steel stamp or plate was not made with mounting features to fit into your press, you can simply set it directly on the area you chose for your mark and, before pressing down on it, check to see that all is centered and aligned. This will ensure even pressure distribution and result in a uniform imprint.

All Steel Stamps & Plates – Preservation and Care

- Do not attempt to use your steel stamps or steel plates for marking hardened steel. Hardened steel products cannot be stamped with steel stamps.

- When you're not using your steel stamps, to prevent rusting, we recommend that you store your stamps in a dry, airtight container. A Tupperware container or a cookie tin box should do the trick.

- Oiling your steel stamps before you store them will also protect them from rusting. Canola oil will do just as well as a product called All Purpose Lubricant.

- If you live in humid climate and find that your steel stamps have some rust on them, you can use a dry Scotch Bright scouring pad (a dish-washing pad) to remove the rust.

- A Steel Sandpaper sheet can also be used. Make sure to avoid scouring or sanding the face of your stamp so it doesn't get scratched or rough.

- When you're done removing the rust off the shaft of your stamp(s), wipe it off with a dry paper towel or clean cloth and oil them promptly thereafter.

-

The TagMate Tag Marking System

Additional tools you will need: A 16 oz. hammer, a pair of safety glasses and padded gloves (recommended).

- Set the TagMate base on a standard steel bench block or similar hard work surface..

-

Secure the Jewelry Metal Tag in the milled recess on the TagMate base, making sure it is flat and secure.

-

Place the TagMate cap over the base by aligning the flat sections of both the cap and base. Look through the opening to make sure the tag is still secure.

-

Insert the TagMate stamp face down into the cap opening by matching its flat vertical surface to the flat section of the cap opening.

-

Hold the cap with one hand and, with the hammer in your other hand, strike the stamp with using moderate force.

-

Lift the TagMate cap with inserted stamp together for increased efficiency while holding it between your thumb and forefinger. Remove the freshly stamped tag. Some test markings may be needed to achieve the desired force and resulting depth of impression.

-

Repeat the previous steps to mark as many Jewelry Metal Tags as needed.

Is marking the tags one at a time interfering with your other tasks? We also offer a tag stamping service to mark the purchased tags and deliver them stamped with your logo! The stamp is then held at our facility for future orders, making this a cost effective option.

-

Brass Stamps & Plates for Marking Soft Materials

- Place the face of your stamp on the spot you chose for your imprint, make sure it is vertical (not tilted) and gently press it into the surface.

- Carefully lift your stamp straight up (avoid tilting) and remove.

- If your mark is too shallow, repeat steps # 1 & # 2 with added pressure.

Marking Tooling Leather (leather that will take and hold an imprint)

- Use only in a non-impact press such as a manual arbor press or a hydraulic press.

- Set your plate on your product, making sure both are centered under your press shaft, to ensure even pressure distribution.

- For further instructions, refer to your specific press manual.

Preserving the Integrity of Your Brass Stamps and Plates

- Use these products only for imprinting the materials you had originally intended to stamp when you purchased them and as indicated on your Sales Order

- If you would like to remove any residue (such as pottery clay, soap, etc.) a wet soft, non-abrasive sponge will do the trick.

- When not in use, wrap up your brass stamps in clean soft cloth to protect them from getting nicked or scratched.

- Make sure you never throw your brass stamps into your toolbox with sharp objects if they are not properly wrapped in protective cloth.

- Brass stamps are rust resistant and, therefore, do not need to be stored in an airtight container. Oiling them is not necessary either.

-

Magnesium Plate Stamps

- Use only in a non-impact press such as a manual arbor press, clicker press, or hydraulic press. These plates should not be struck with a mallet or hammer.

- If using a arbor press or hydraulic press, a backing plate must be used between the magnesium plate and your press shaft to avoid damaging the soft magnesium die.

- Set your plate on your product, making sure both are centered under your press shaft.

- For further instructions, refer to your specific press manual.

Tips:

- When not in use, wrap your magnesium plates in a clean soft cloth to protect them from getting nicked or scratched.

- Make sure you never throw them into a toolbox with other sharp objects if they are not properly wrapped with a protective cloth.

-

Steel Type for use in Handheld and Machine Holders

Tools you will need: Safety glasses, 16 oz. hammer (for handheld holders), Gloves (recommended). Utilize a workbench that is level, smooth and free of debris. A tempered steel marking bench block is highly recommended.

- Pick up your type holder and insert the steel type pieces that will make up the specific imprint you need.

- If the character pieces don’t fill up the entire opening of your holder, insert as many spacers as necessary (provided) to take up the remaining open space.

- Use Allen wrench (provided) to tighten the set-screw located on the side of the head of your holder until the type pieces and spacers are secured in place.

- Set your holder with inserted type head down on the area you wish to mark and make sure it is in full contact.

- Hold your type holder firmly vertically (avoid tilting) in one hand and with your other hand, holding a 16oz hammer, strike the top end of your holder with moderate force and only once (to prevent a double-image).

- If your first imprint is too shallow, increase the force of your strike for additional imprints.

Preservation and Care

- Do not attempt to use your steel type and holder for imprinting hardened steel. Hardened steel products cannot be imprinted.

- When you’re not using your steel type and holder, to prevent rusting, we recommend that you store them in a dry, airtight container. A Tupperware container or a cookie tin box should do the trick.

- Oiling your steel type before you store them away will also protect them from rusting. Using Canola oil is just a good as a product called All Purpose Lubricant.

- If you live in a humid climate and find that your steel type and holder have some rust on them, you can use a new dry dish washing scouring pad to remove the rust. A Steel Sandpaper sheet can also be used. Make sure to avoid scouring or sanding the face of your steel type so they don’t get scratched or rough.

-

Hand Stamp Holders

- Hold the plastic handle of your stamp holder in one hand and with your other hand hold the C shaped head.

- Twist handle counter clockwise until only a small portion of the screw remains inside the C head.

- Place the center of your stamp inside the groove located at the top of the C shaped head.

- Turn the handle of your holder clockwise until its screw comes into contact with your stamp.

- Continue turning the handle and tighten contact with stamp until it is firmly locked in place and will not budge.

- Set the face of your stamp on the spot you wish to mark and, just before you strike the top your stamp with your 16oz hammer, make sure it is in full contact with the surface of your product.

- Strike your stamp with moderate force and only once (to avoid a double-image imprint).

- If you find that your first imprint is too shallow, increase your striking force for additional imprints.

-

Manual Impact/Percussion Presses

- Load and position your steel stamp or steel type holder in the press collet and tighten with locking nut (provided) to secure in place. Do not over-tighten as it may damage collet.

- Position your product practice-piece on press table or fixture to test-mark.

- Adjust the height of the marking head from your practice piece so that impact occurs. If impact does not occur, see step 7 below.

- Use the knurled nut or handle to adjust marking load by compressing or releasing the load spring.

- If the marking load (pressure) is insufficient, fit stronger spring and repeat step # 4.

- If impact fails to occur ensure that initial spring resistance is overcome. (See step # 3 above).

- If resistance is not overcome even though the machine height is correctly set, ensure that the quill has fully returned. If not, suspect the return spring is sticking. Also check for a broken spring.

- If return spring isn't functioning correctly, the lock nuts on the quill may be set too close to the nut above. This distance can be slightly increased but the gap should be kept as close as possible to minimize the possibility of damage to the internal mechanism.

- If the reason for failure is unclear, check for broken ball bearings. If you find that they are, check for internal damage. If none of them are broken, replace and re-assemble.

- This step applies to the 3-ton press: In order to avoid a double imprint, ensure that the two nuts located above the collet nut are both in contact with the rubber ‘O’ ring at the point of actuation.